Roll Out Cantilever Rack in Michigan n SRS Shelving+Rack Systems

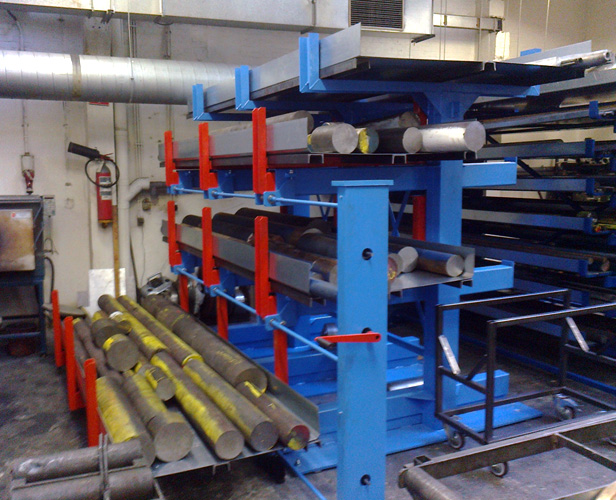

Get Roll Out Cantilever Rack Now. Our team of cantilever racking professionals can help you find the perfect roll out rack system, or any other cantilever/pallet rack system that is right for you. Get a quote now or give us a call at (888) 680-2256. Roll out cantilever rack is a drawer-like storage system that allows you to save valuable floor.

Roll Out Cantilever Racks Get a Quote

The automated roll out cantilever rack consists of a series of roll out cantilever racks mounted on rails. Thanks to these rails the racks can be moved electrically. Just like the standard roll out cantilever rack, this system is suitable for the compact storage of all types of long profiles. Pipes, profiles, bars, hollow sections, bars, flat.

Roll out cantilever rack Eurostorage Storage profiles

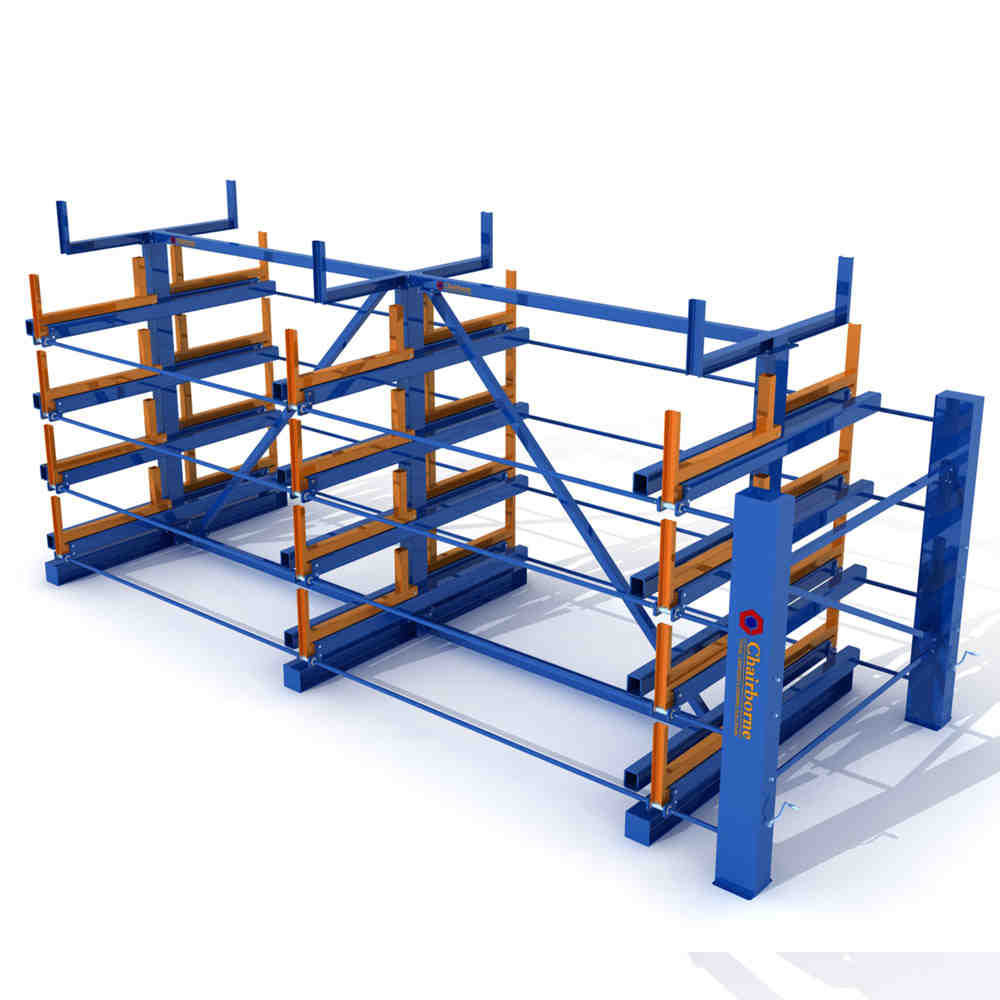

Cantilever Racking. Global cantilever racking systems are some of the most versatile racking systems in Australia. Unlike pallet racking, Global cantilever racks are adaptable, flexible and strong, capable of supporting a range of long-form, awkward, oversize and heavy items - and they are designed and manufactured to FEM 10.2.09 and can be certified for all types of Australian conditions.

Roll Out Cantilever Rack Canadian Rack Technologies Inc.

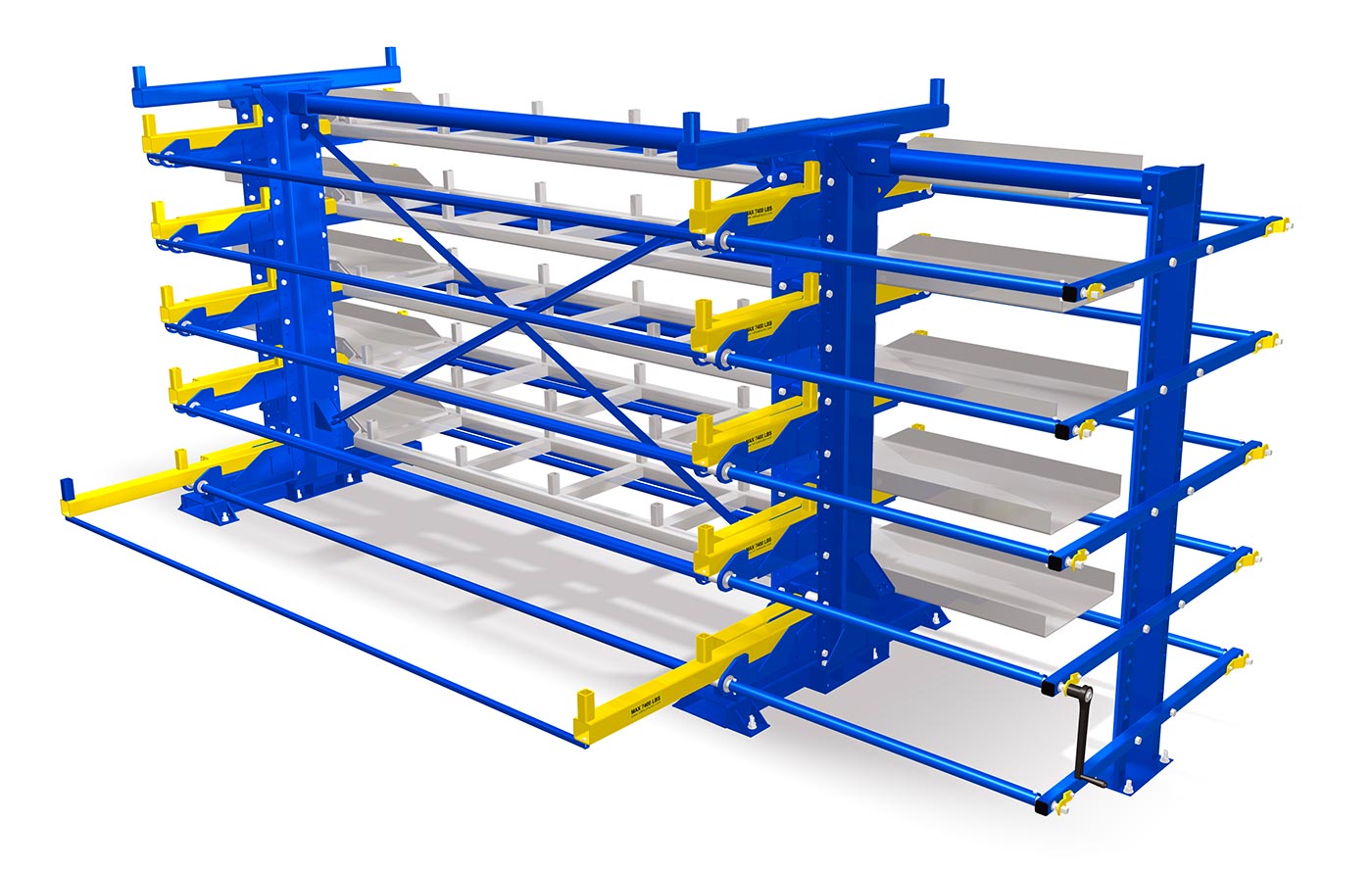

The roll-out cantilever rack is very user-friendly.. Only 1 person is needed to execute the handling. With a handle the operator can easily open the drawer. This task requires little energy, effort and time, even in the case of a heavy load. Thanks to the 100% extendable drawers, you have full access to each long profile.

Roll Out Cantilever Rack Roll Out Racks

The Roll Out Cantilever Rack (commonly known as a bar rack or pipe rack) allows you to store long materials inside a drawer system. With this rack, you can free up to 50% of your floor space, and your employees will no longer have to find material by digging through dangerous piles. In the end, this greatly increases time optimization and safety.

Roll Out Cantilever Rack Cantilever Rack System

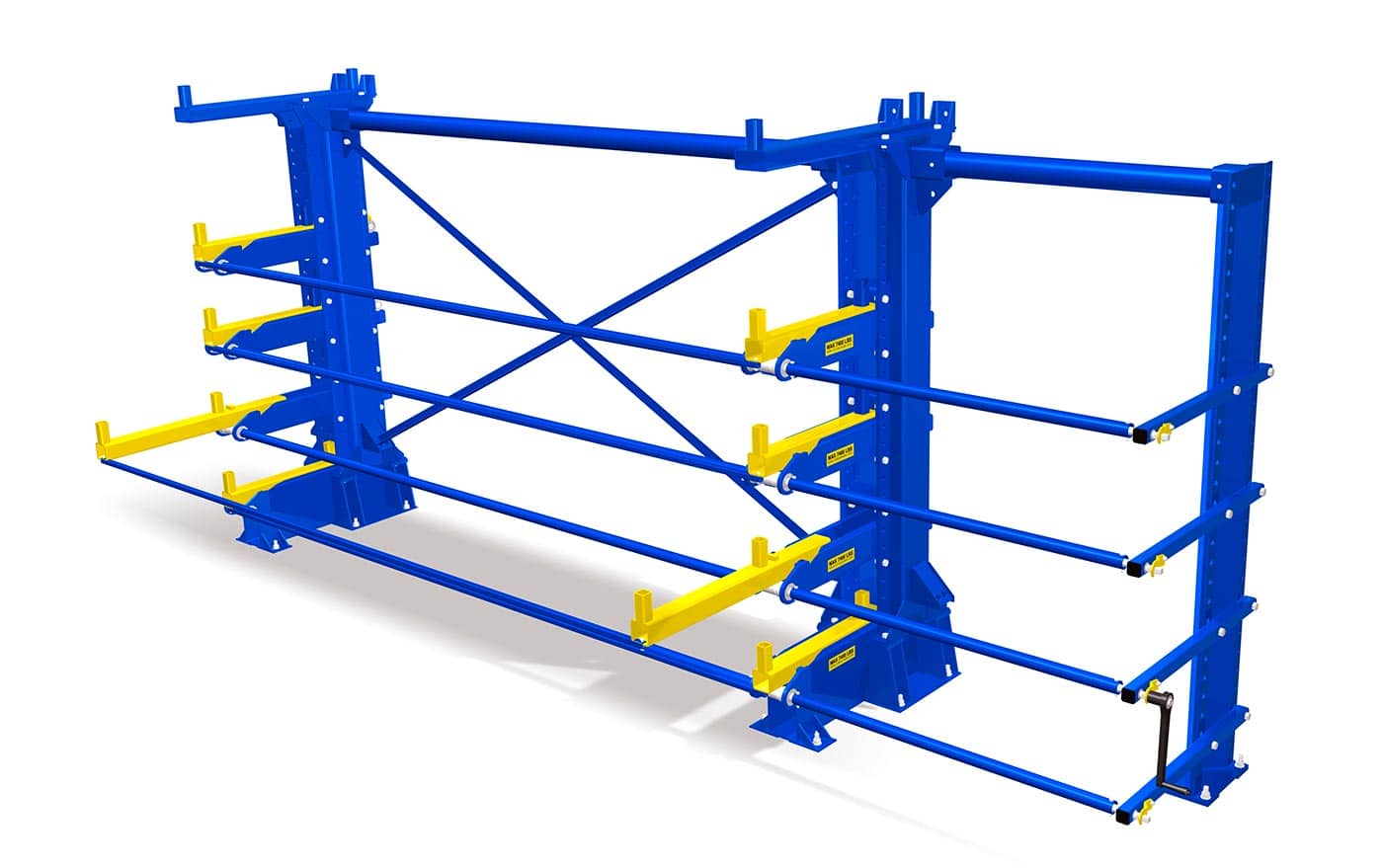

Practical applications for Single-Sided Cantilever Racks include storing tooling and fixtures in proximity to press brakes, shears, and other processing equipment, storing items sold in bulk, and storing fast-moving inventory. A standard model with four roll-out cantilever drawers (4T) can store up to twelve tooling and fixture combinations.

Roll Out Cantilever Rack Dynamic Material Handling Solutions

The Roll Out Cantilever Rack (commonly known as a bar rack or pipe rack) allows you to store long materials inside a drawer system. With this rack, you can free up to 50% of your floor space, and your employees will no longer have to find material by digging through dangerous piles. In the end, this greatly increases time optimization and safety.

Roll Out Cantilever Racking Rack Storage UK

The Roll Out Cantilever Rack (commonly known as a bar rack or pipe rack) allows you to store long materials inside a drawer system. With this rack, you can free up to 50% of your floor space, and your employees will no longer have to find material by digging through dangerous piles. In the end, this greatly increases time optimization and safety.

Q235 Steel Spacesaver 4000kgs/level Roll Out Cantilever Rack SGS

SpaceSavers can increase storage and production capacity as much as five times current levels, and these roll-out cantilever racks provide additional storage space by utilizing the cube in receptacles up to 20' high. A SpaceSaver Rack is a series of double-sided, vertically stacked receptacles available in any number of levels up to 8 levels.

Roll out Cantilever Rack Single Sided YouTube

It combines the flexibility of a cantilever rack system that allows you to store varying length products while proving the efficiency of a roll out rack system. Roll out rack allows you to pick products with use of a forklift or overhead crane. Arm levels roll out easily allowing ergonomic efficiency. 124″ tall x 57″ deep single side / 95.

Roll Out CantileverRoll Out Cantilever Crank Out Cantilever steel

The roll-out movement is controlled and limited by the depth of the shelf arm. The ratio of spindle shaft to crank rotation is 2.36: 1. With a full load of 5.000 kg, an initial crank force of approx. 15 kg may be required. After that, only little force is necessary. Each rack unit consists of at least two base structures, longitudinal binders.

Roll out cantilever rack Eurostorage Storage profiles

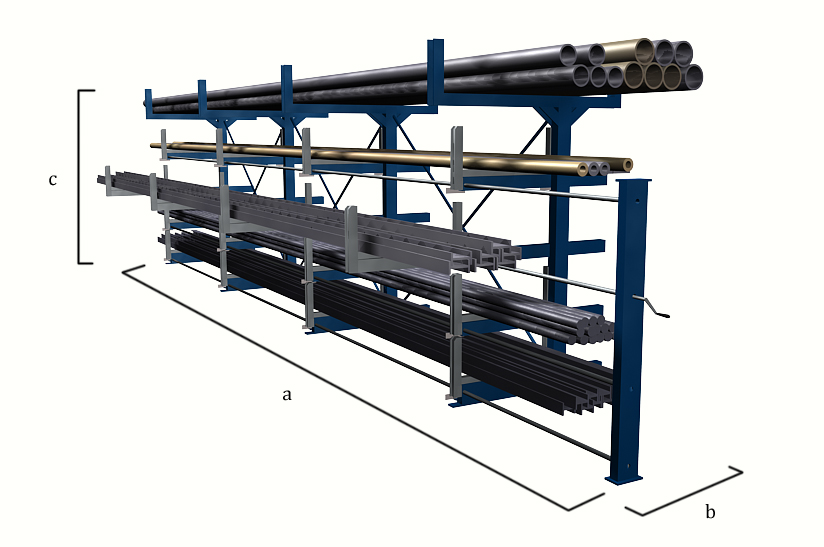

After introducing the Roll Out Cantilever Rack to your workspace, your operations will become more profitable and safer. Specifications of the Roll Out Cantilever Rack. Shelf lengths: 20', 24' or 40'. Height: 100", 124", 148" or 184". Drawer depths: 20", 24" or 36". Drawer capacity: 6,000 to 16,800 lb.

Roll Out Cantilever Rack Products King Materials Handling

Cantilever racks allow you to get stock (like steel, aluminium, or iron) into racks off the floor.Rack systems combine storage density with selectivity for s.

Roll Out CantileverRoll Out Cantilever Crank Out Cantilever steel

You would like to learn more about our products? Contact us now! Our specialists are available to answer all your questions. 1-833-647-2257. The most efficient industrial storage and shelving solutions on the market. We offer a fast and quality service, discover our wide range of products.

Roll Out Cantilever Rack Products King Materials Handling

Roll Out Rack systems, including cantilever racking, roll out sheet rack, and roll-out pallet racking, are a trio of versatile storage solutions designed to enhance accessibility and organization within industrial environments. Whether you're dealing with long, unwieldy items in need of efficient storage, or looking for a streamlined solution for sheet metal materials, or even optimizing the.

Roll out cantilever rack Eurostorage Storage profiles

Roll Out Cantilever Rack. The Roll Out Cantilever Rack (commonly known as a bar rack or pipe rack) allows you to store long materials inside a drawer system. With this rack, you can free up to 50% of your floor space, and your employees will no longer have to find material by digging through dangerous piles. In the end, this greatly increases.