Strange Noise On Singapore Airlines A380 — Tech Ops Forum

Eaton's 5,000-psi hydraulic pump design to power primary flight controls, landing gear and nose wheel steering on the Airbus A380 debuted this week at the supplier's facility in Jackson, Miss..

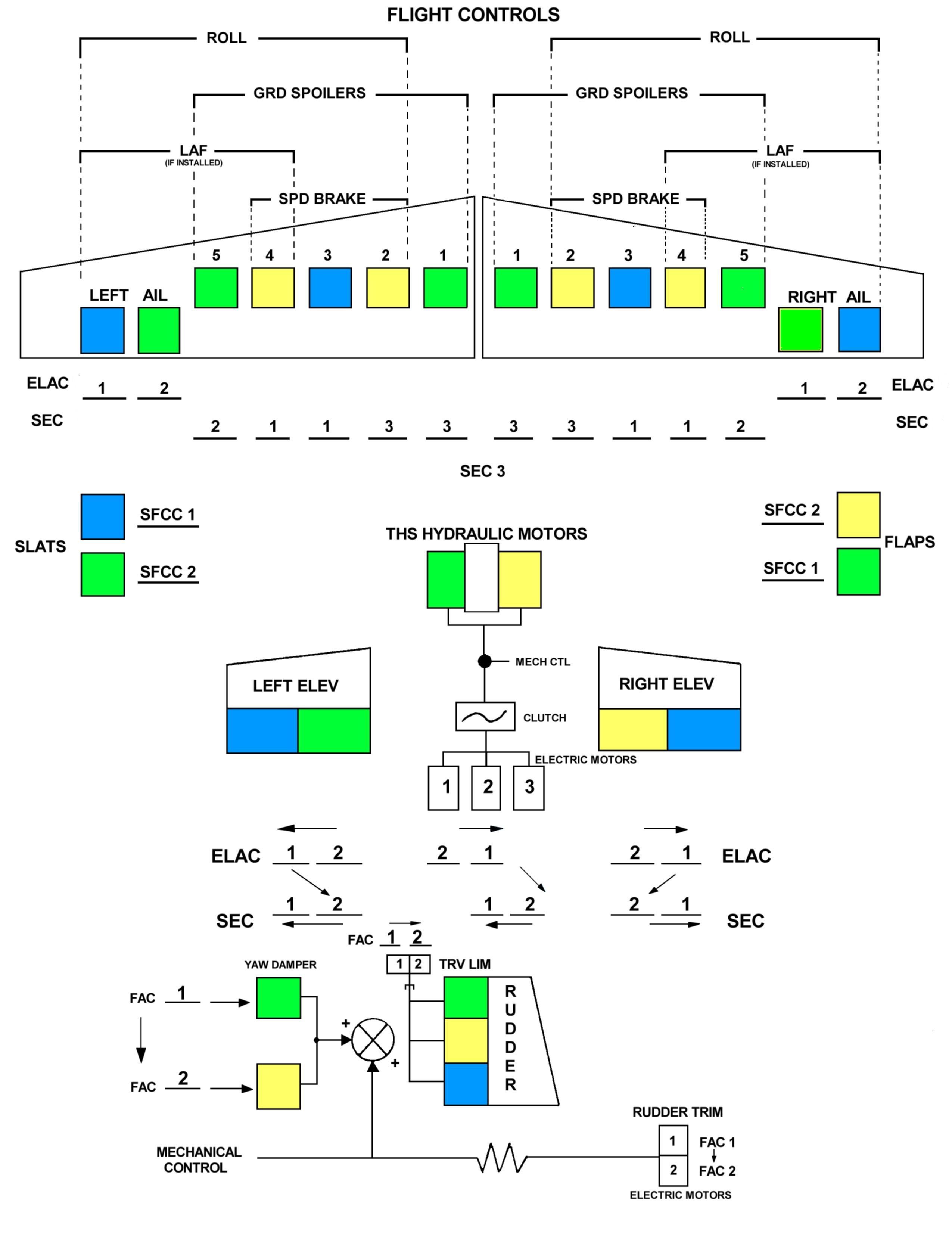

Flight Controls

Why the A380 and A350 have only two hydraulic systems - YouTube 0:00 / 3:21 Why the A380 and A350 have only two hydraulic systems Aviation News and Information (AvNews.info) 119.

Aircraft Hydraulic System Design

High Pressure Hydraulics for the A380. Robert W. Moorman September 01, 2005. Picture a several-story apartment building turned on its side with enormous swept wings lumbering down the runway. At.

A380 pushes 5000 psi into realm of the common man Hydraulics & Pneumatics

A380 pushes 5000 psi into realm of the common man | Power & Motion The A380, which will seat 555 passengers and travel up to 8000 mi without refueling, is planned to be operational in early 2006. It takes the double-decker concept from rival.

Flying Lessons New engine, new airplane, new jumbosized worries

A380 wing area is 845m2. This enables the A380 to land 20 knots i.e. 35kmh slower than. 747 at its maximum landing weight of 386 tonnes, and contributes to reduce noise around airports. The span of the horizontal stabiliser is 30.4 m, this is just a bit less than the span of an A320 wings (34.9 m).

PPT Aircraft Hydraulic System Design PowerPoint Presentation ID2945578

The Abex Division, Kalamazoo, Mich., supplied hydraulic motors, and the Abex Aerohydraul Division, Mainz-Kastel, Germany, supplied variable-displacement hydraulic motors for the A380's flap system. The two-deck, four-aisle A380 will seat 555 passengers. It will begin commercial flights in 2006.

为什么波音737没有 ram air turbine(冲压空气涡轮)? 知乎

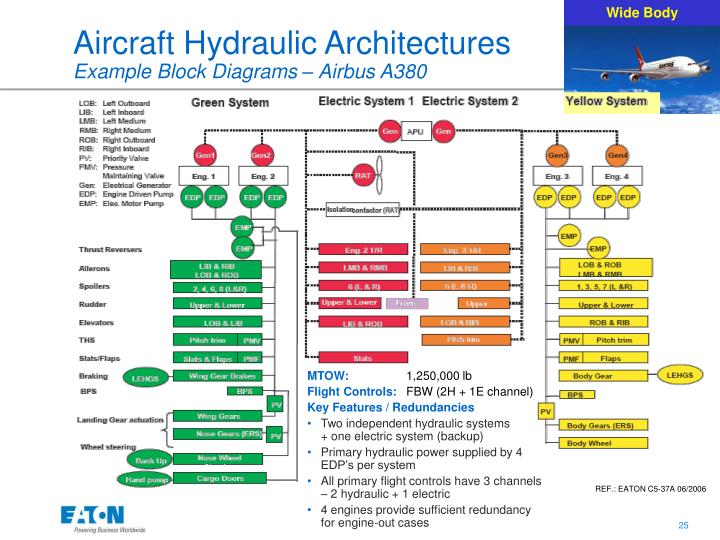

The A380 "More Electric" flight control actuation concept consists in eliminating one hydraulic system and replacing it with a set of electrically powered actuators, with no detrimental impact to the probability of loosing the flight control actuation system.

Aircraft Systems Aircraft Hydraulic System Pumps

16 December 2021 Commercial Aircraft The A380, Emirates and flying public : A winning combination Emirates received its 123rd A380 in Hamburg on December 16, 2021. The close collaboration with Airbus has shaped the identity of the A380 over the years and continues to transform the passenger experience today.

A380 Hydraulic Test Equipment

The new hydraulic system (with a 5000 psi pressure and the 2H/2E systems architecture where the traditional three hydraulic circuits were replaced by two hydraulic and two electric systems), reduced weight, and improved system redundancy and reliability. The A380 of tomorrow relies on sustainable aviation fuels (SAF)

Aircraft Hydraulic System All You Need to Know Aircraft Systems

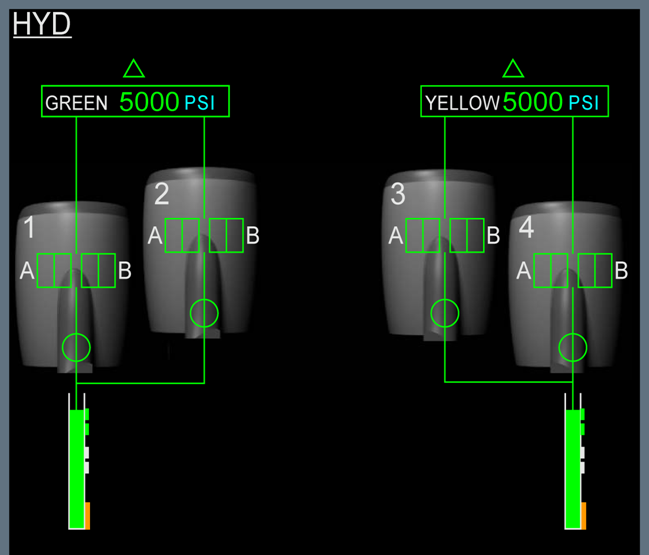

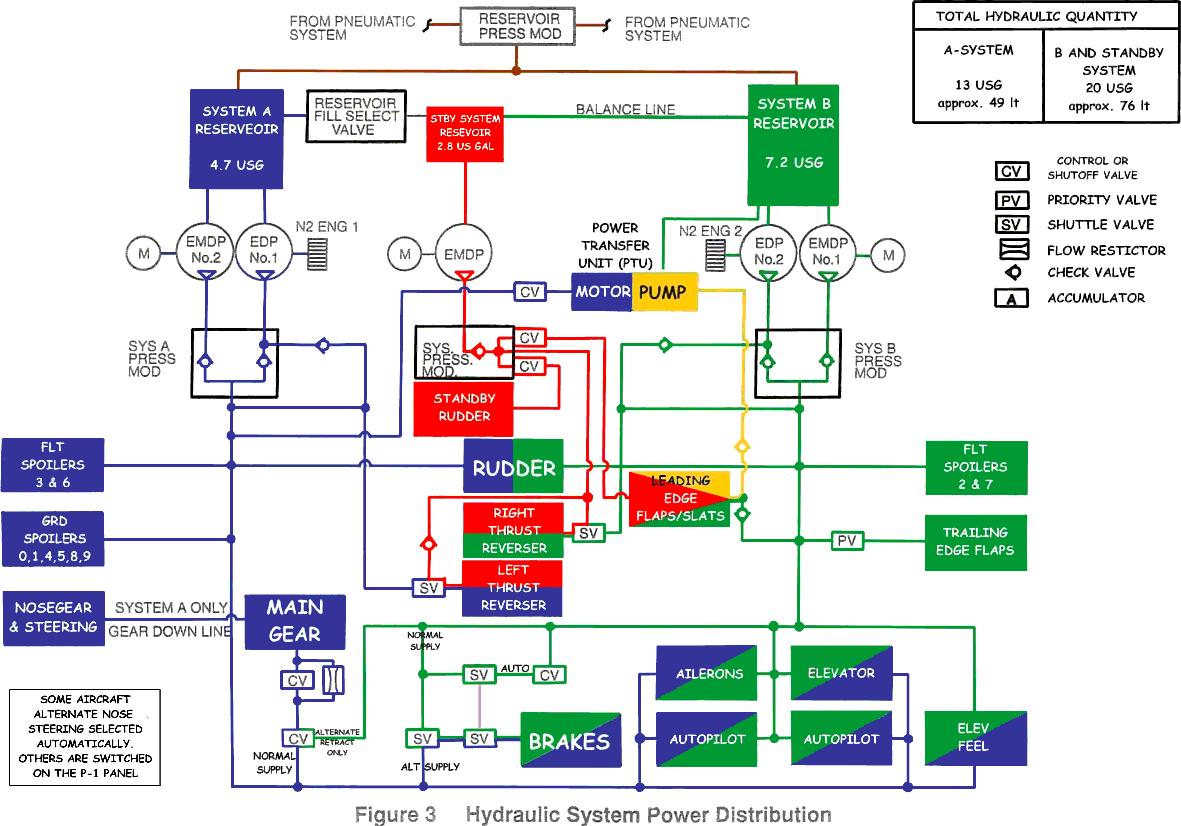

The A380's hydraulic system is split into two independent circuits, green and yellow, powering flight actuators, landing gears, braking, and cargo doors. Hydraulic power is produced by Engine Driven Pumps (EDP) in flight and Electric Motor Pumps (EMP) on the ground.

Dc 10 Cargo Door Schematic

GREEN hydraulic system. Y. YELLOW hydraulic system. E1. E1 AC power (AC1ess side 1) E2. E2 AC power (AC2ess side 2) E3. E3 AC power (AC1 side 1) P1, P2, P3, S1, S2, S3. Prim and Sec Flight Control Computers. E2 E1 B B. BCM ultimate backup control Reconfiguration arrow Electrical Motor. E2 G E1 E2 YE1 THS P2 P1P3 P2. O/B I/B. G ELEVATORS P2 P1 I.

What happens if an aircraft has hydraulic failure Aeropeep Aircraft and Engineering Forum

The pump pressure pulsation can be as low as ±1% in some well-designed systems, for instance the Airbus A380 hydraulic system, and as high as ±10% as allowed in older systems. 2 Thus, it can be seen that reducing the pressure pulsation is a permanent topic for the aircraft piston pump. 4.4. High reliability and long service life

AVION Airbus A380 Hydraulic System

Aircraft commonality The A380 leverages Airbus' expertise in aircraft design, sharing a large degree of commonality in systems, flight deck, procedures, and maintainability with the fly-by-wire A320, A330/A340 and A350 families.

Aircraft systems Large Aircraft Hydraulic Systems

A380 aircraft hydraulic systems Source publication Design of Aircraft hydraulics leakage detection system based on wireless sensor network Article Full-text available Jul 2020 Vishal digambar.

Airbus Study Aids

EHA (Electro Hydraulic Actuator) or EBHA (Electro Backed up Hy-draulic Actuator: fig. 2). This new type of architecture with only two circuits allows the saving of several hundred kilograms on the A380, mainly thanks to the reduction of the number of pipes. It also creates a new level of system segregation safety. Some control surfaces have been

Engineer Airplane Antenna Location

The Airbus A380 is a very large wide-body airliner that was developed and produced by Airbus. It is the world's largest passenger airliner and only full-length double-deck jet airliner. Airbus studies started in 1988, and the project was announced in 1990 to challenge the dominance of the Boeing 747 in the long-haul market.