Machine Drawing Double acting cylinder Pneumatic Circuit

Introduction to Fluid Power Forces in Liquids Hydraulic Fluids Pumps Fluid Lines & Fittings Valves Sealing Devices & Materials Measurement & Pressure Control Devices Reservoirs, Strainers, Filters, & Accumulators Actuators Pneumatics Basic Diagrams & Systems Graphic Symbols for Fluid Power Diagrams Basic Diagrams and Systems

Hydraulic Cylinders Lehigh Fluid Power

Hydraulic Advantages. Hydraulics has many advantages not always found in electrical and mechanical type drives. Hydraulic cylinders and motors can be operated at variable speeds. By varying the volume flowing into the actuator (cylinder or motor) the speed is changed. The hydraulic cylinder or motor can be stalled under a load.

Hydraulic Cylinder Working Principle

The hydraulic cylinders on this excavator operate the machine's linkages. Hydraulic cylinders in a hot press of a particle board machine. A hydraulic cylinder (also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment (engineering vehicles.

The Parts of a Hydraulic Cylinder It Still Runs Your Ultimate Older

A hydraulic cylinder schematic diagram provides a visual representation of the different components and fluid flow paths within a hydraulic cylinder system. By studying these diagrams, engineers and technicians can gain valuable insights into the functionality and performance of hydraulic cylinders.

Hydraulic Cylinders, Cylinder Parts and Hydraulic System Parts Supplier

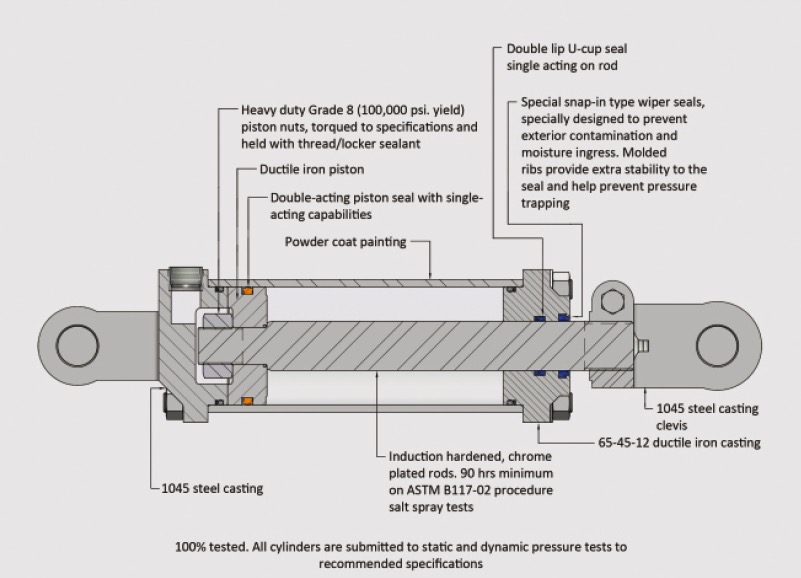

Fτ = P∏ (r12 - r22 ) Where: Fτ is the resultant force. P is the pressure distributed load on the surface. ∏ is pi, approximately equal to 3.14159. r1 is the radius of the piston. r2 is the radius of the piston rod. In hydraulic cylinders, the force can easily be multiplied or divided throughout the system.

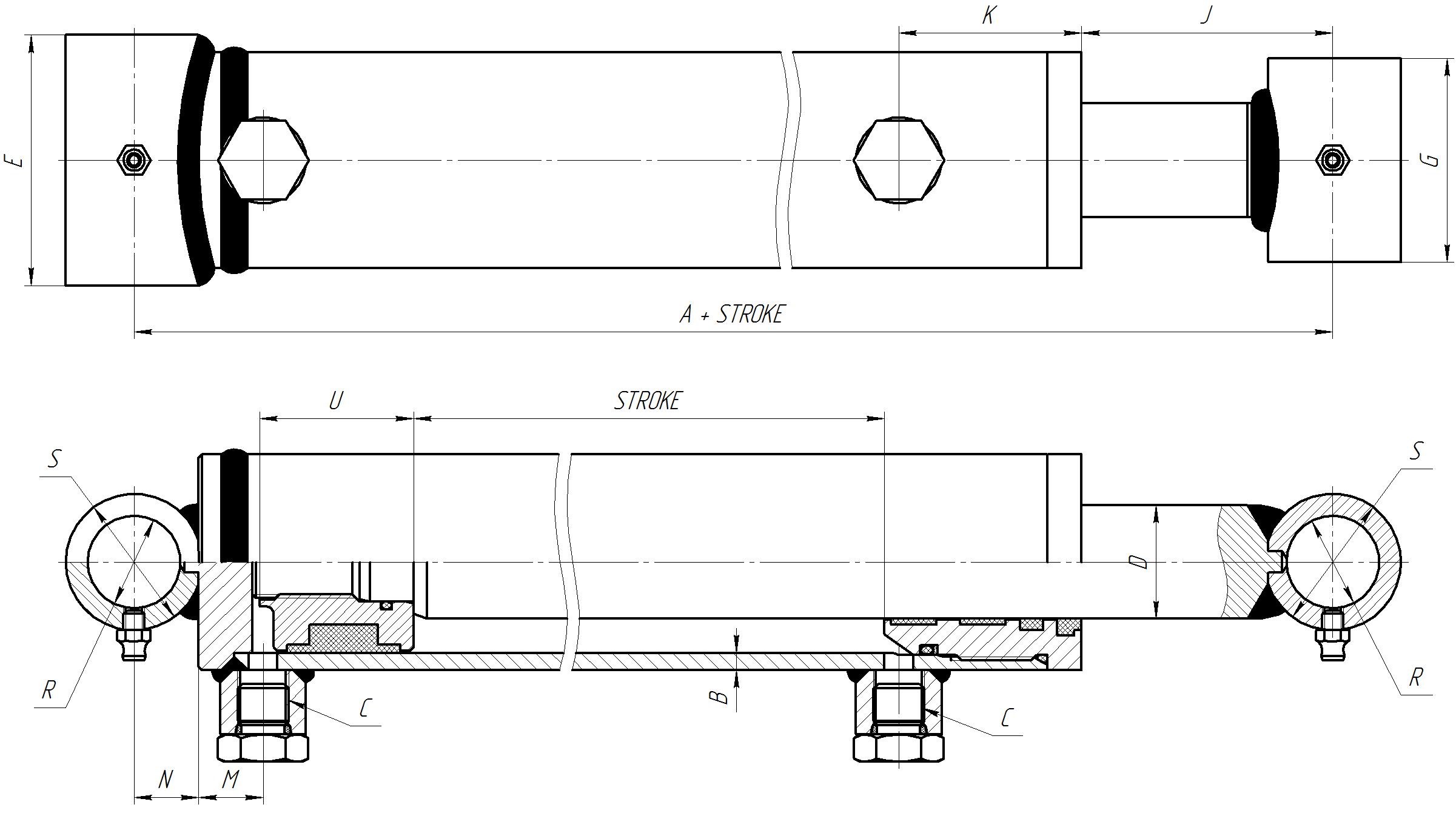

How to measure a hydraulic cylinder replacement? Magister Hydraulics

The basic drawn lines, cylinder symbols, ejector symbols, and the Do Not Scale note are just a handful of items that are particular to engineering drawings for hydraulics.. Cylinders do the major work in a hydraulic system but in a hydraulic press, an ejector is also needed. Both components utilize the same basic symbol and it's another.

The Function of Seals In a Hydraulic Cylinder หน้าที่ของซีลในกระบอกไฮดรอลิก

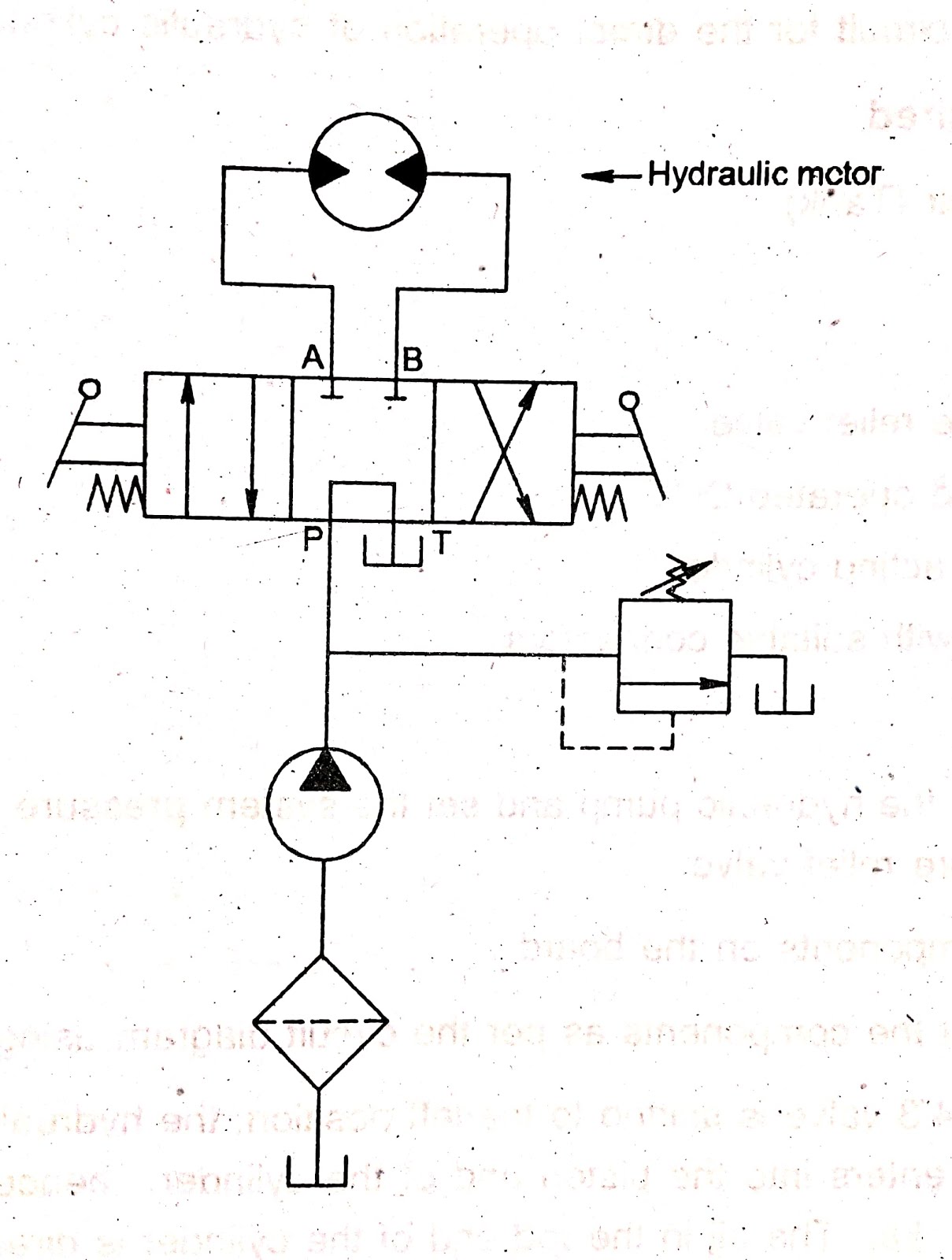

Simple Hydraulic System Hydraulic Schematic Symbols Accumulator Cylinder Double acting Directional Control Valve (manually operated) Dump Pumps Hydraulic System Components: Gear Pump Hydraulic Pump Symbol Hydraulic System Components : Accumulator Accumulator symbol Hydraulic System Components : Directional Control Valve

The 25+ best Hydraulic cylinder ideas on Pinterest Mechanical

The function of a cylinder in a fluid power system is to convert energy in the fluid stream into an equivalent amount of mechanical energy. Its power is delivered in a straight-line, push-pull motion. Graphic Symbols: Following diagram illustrates standard ANSI (American National Standards Institute) graphic symbols for use in circuit diagrams.

If it’s an older system, it could be that the hydraulic cylinder is

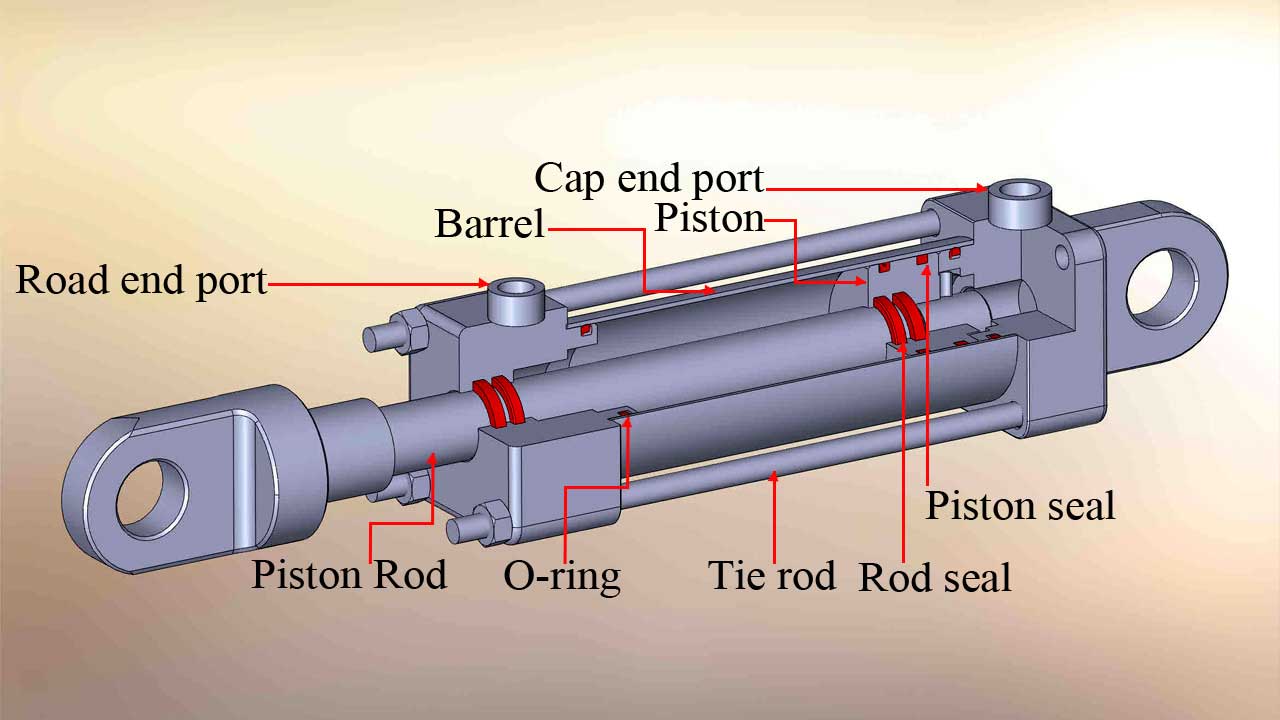

A hydraulic cylinder is the actuator or 'motor' side of the system. The 'generator' side of the hydraulic system is the hydraulic pump which brings in a fixed or regulated flow of oil to the bottom side of the hydraulic cylinder, to move the piston rod upwards. The piston pushes the hydraulic oil in the other chamber back to the reservoir.

35 How To Rebuild Hydraulic Cylinder Diagram Wiring Diagram List

2. Remove the external steel wire ring. 3. Remove any dirt that may have accumulated on the cylinder head. 4. Using the mallet and punch, push the head into the cylinder tube until the. is fully exposed. This will also move the internal wire ring into its removal position. 5.

How to Rebuild a Hydraulic Cylinder Intella Parts Company, LLC

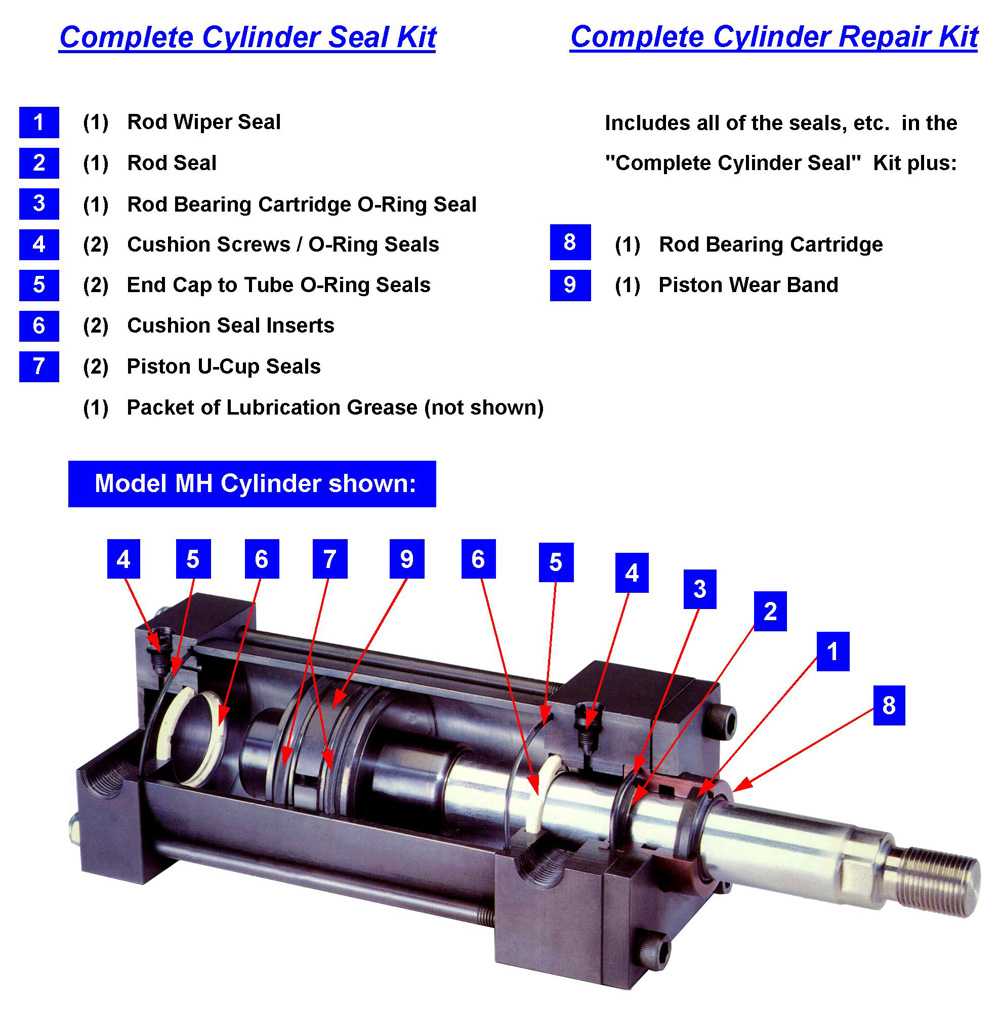

series 2A air cylinders. Optional for series 2H, 3L & VH hydraulic cylinders. Hi-Load Type Piston Optional on series 2H & VH hydraulic cylinders. Not available on series 2A & 3L cylinders. Series 2A Series 2H, 3L & VH S eries 2A & 3L S eries 2H & VH Bore Contains 2 Ea. Contains 2 Ea. Cylinder Body Material Size Symbol 47 Symbol 47 Brass Steel.

Hydraulic Cylinder Hyspecs Hydraulics Australia

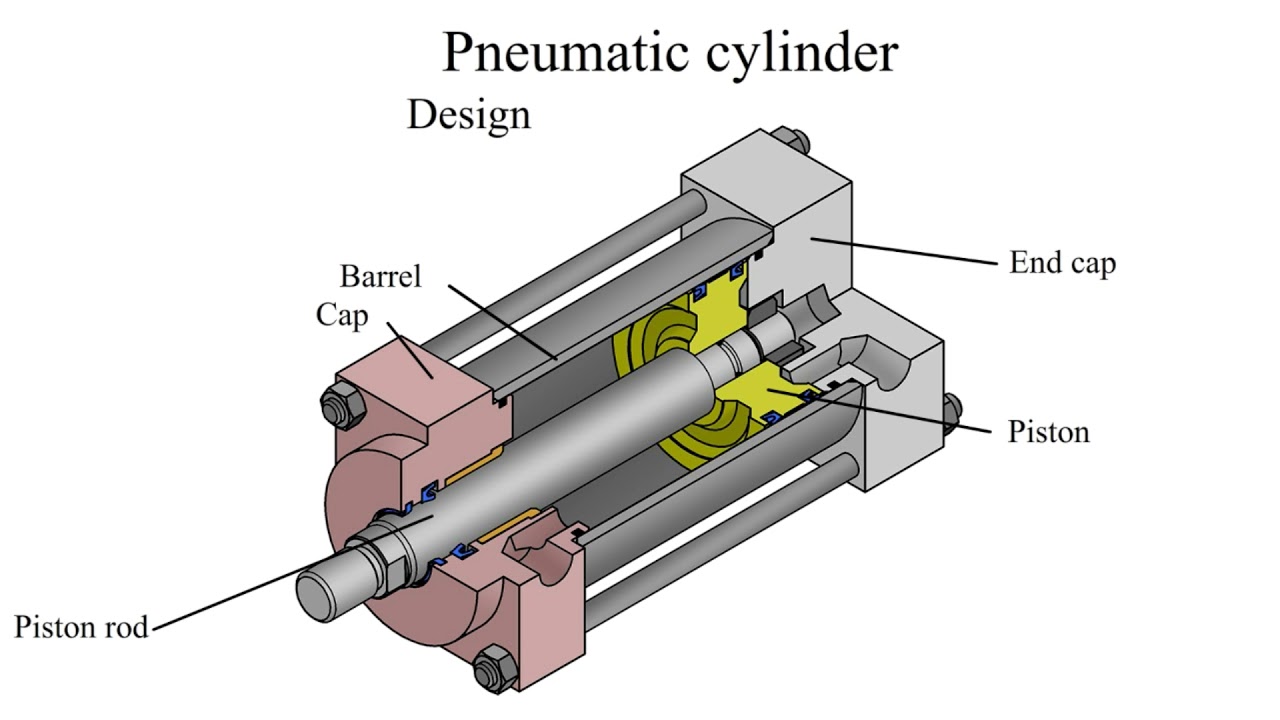

A simple diagram below helps explain the mechanics of the process -- as fluid enters a chamber more force is applied to push or pull the piston rod in or out of the cylinder and, in turn, pivot, push, or pull the component the cylinder is connected to. Hydraulic cylinders come in two types: single acting and double acting.

Peninsular Cylinder Co. cylinder repair, hydraulic cylinder repair

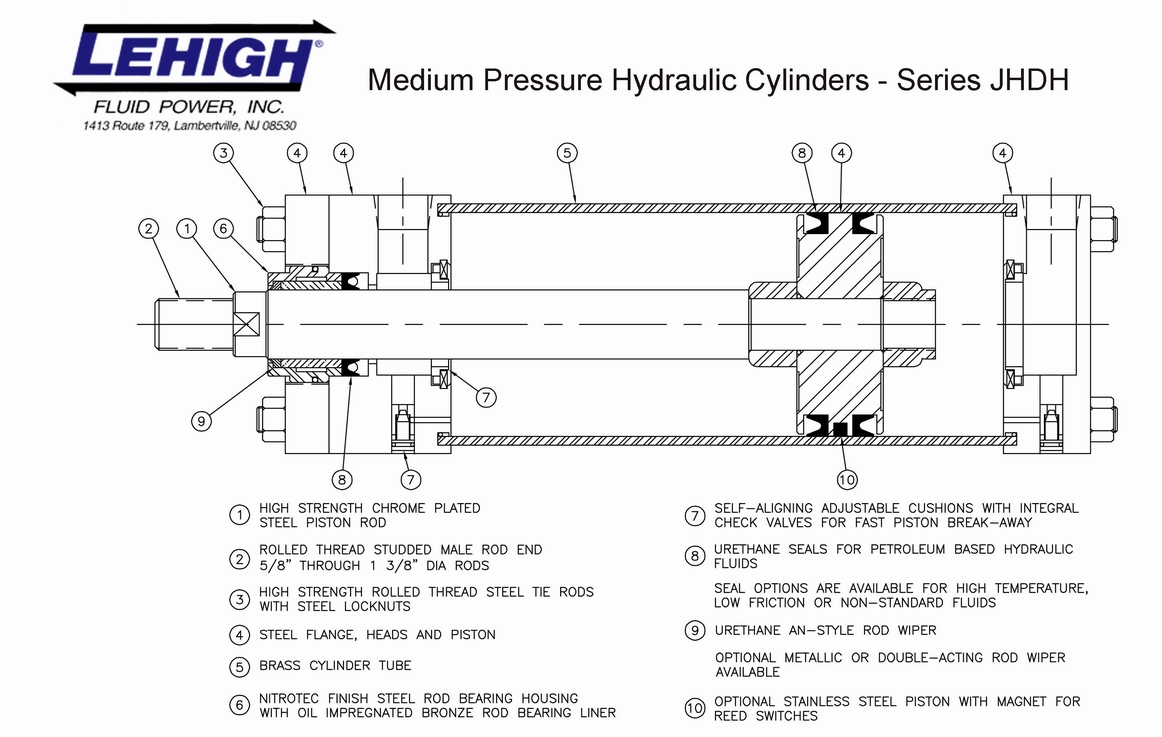

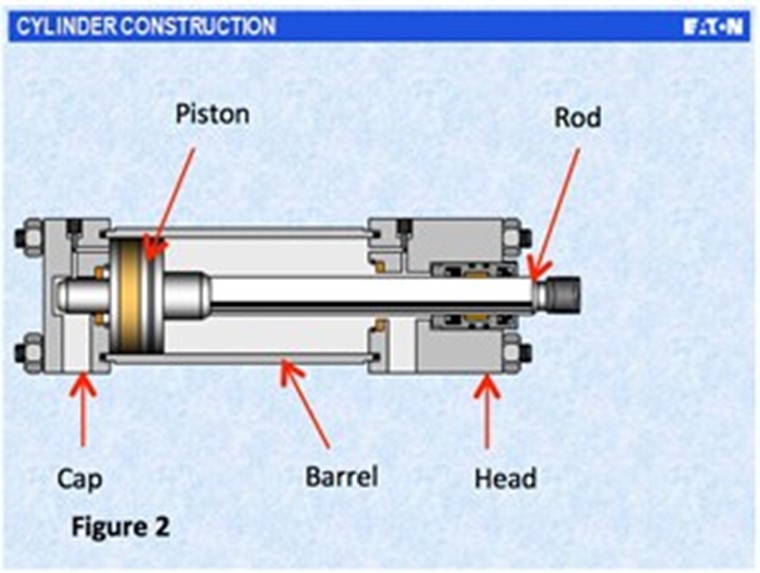

1.3 Hydraulic Cylinders. Define the term actuator and give examples of a rotational electrical actuator and a linear hydraulic actuator. Draw a pictorial diagram of a double acting hydraulic cylinder. Identify the barrel, piston, rod, cap end plate, rod end plate, rod wiper, cap end port, and rod end port. NOTE: the rod end is often called the.

What Are The Parts Of A Hydraulic Cylinder? Anbao Hydraulic

Piston Rod Typically made from cold-rolled steel fortified with hard chrome plating, the piston (cylinder) rod is attached to the cylinder head and the piston. Hard chrome is essential for giving piston rods the ability to last a long time. The piston rod also enhances the seal, which helps prevent leaks. Seal Gland

What is a Hydraulic Cylinder with Hydraulic Cylinder Diagram

A hydraulic cylinder has eight basic components; the clevis, gland, port (s), barrel, rod, piston, the end cap, and the seal. When combined, these parts allow the hydraulic cylinder to pressurise fluid that mobilises a piston to generate power for a machine.

HYDRAULIC SYSTEM FOR BEGINNERS Mechanical Engineering Professionals

The term cylinder is commonly used to describe a device that gives linear force output and movement. A cylinder may also be referred to as a linear actuator. Cylinders are broken down into two main categories: pneu-matic and hydraulic. Pneumatic cylinders can be operated by several types of gases; however, compressed air is by far the most common.